Product Service

02

Metal stamping

We have developed very close relationships with several vendors who are capable of handling very high-volume programs while maintaining very tight tolerances and ensuring the highest level of quality in the industry. We have also incorporated assembly automation that allows us to stamp and then assemble multiple components to provide a finished product.

04

Automation

We have several houses or suppliers that can assist our customers on a case-by-case basis in implementing automation when requested to help control quality and reduce costs by eliminating labor.

06

Laser printing

Part decoration . We have a variety of options that include traditional pad printing that we have done for a wide range of products. We have recently used a new technology called laser printing that is applied with laser precision and cured with UV lights. This process has been very well received by our customers for certain applications that require precise or tight tolerance applications.

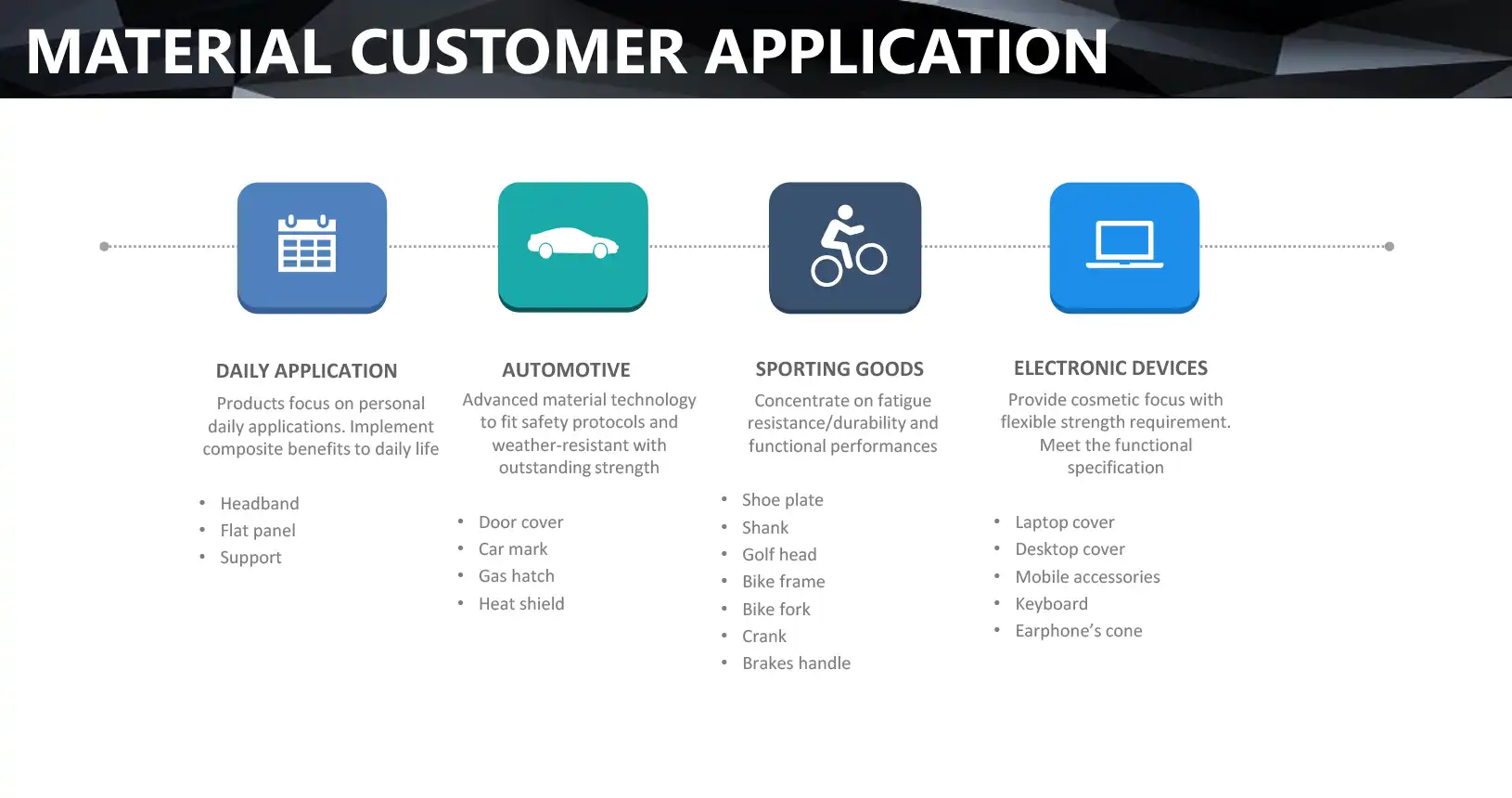

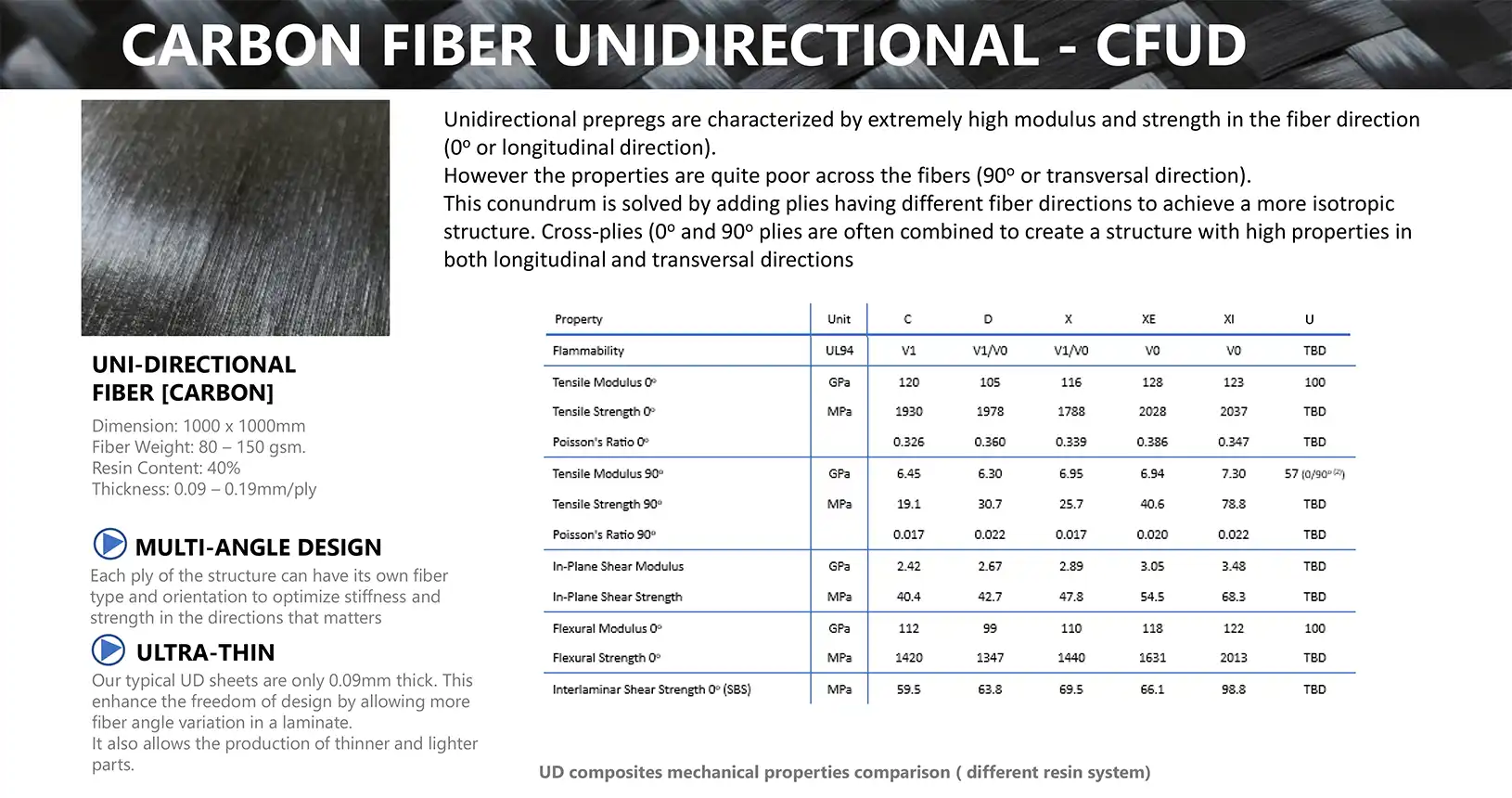

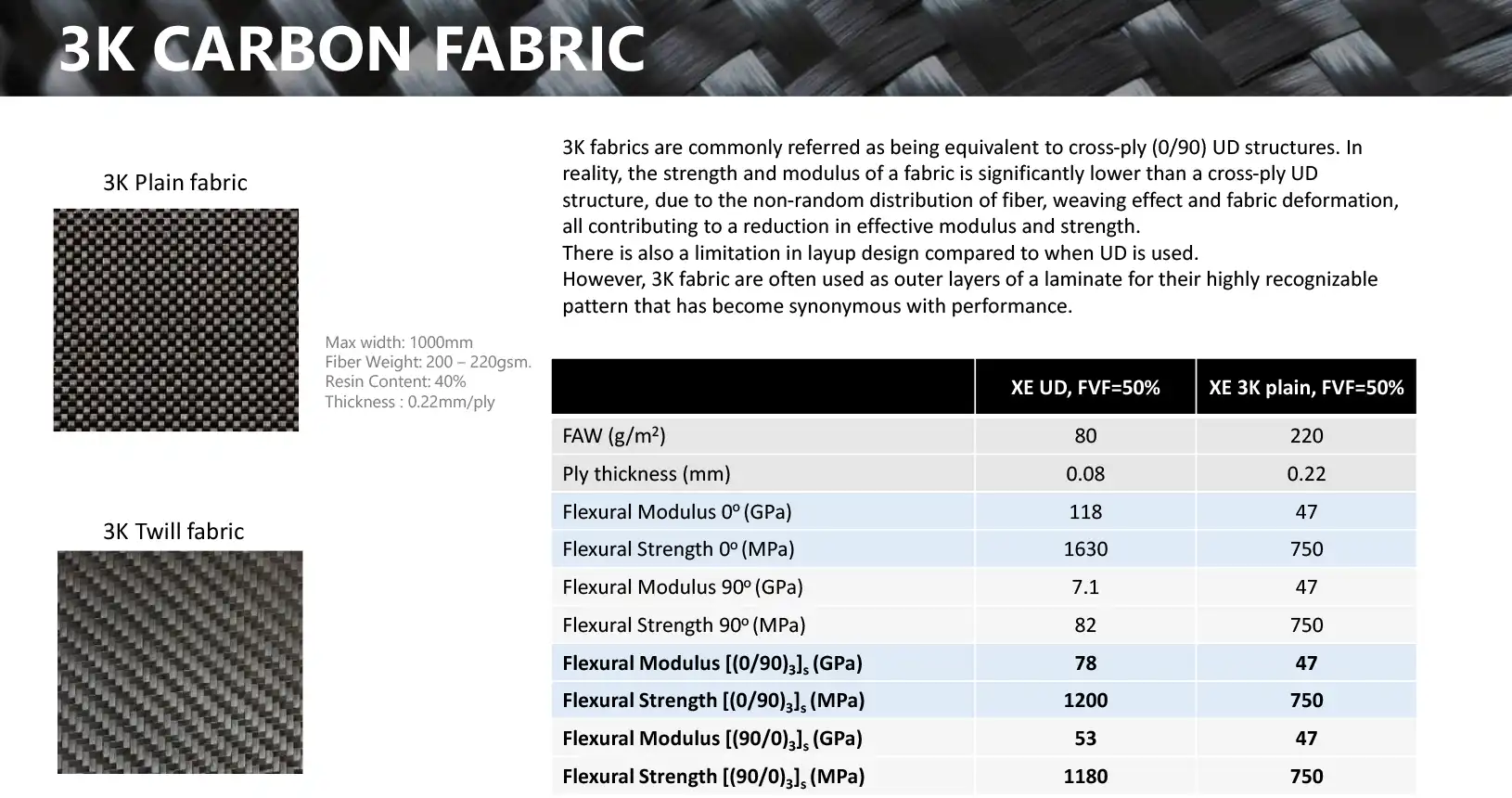

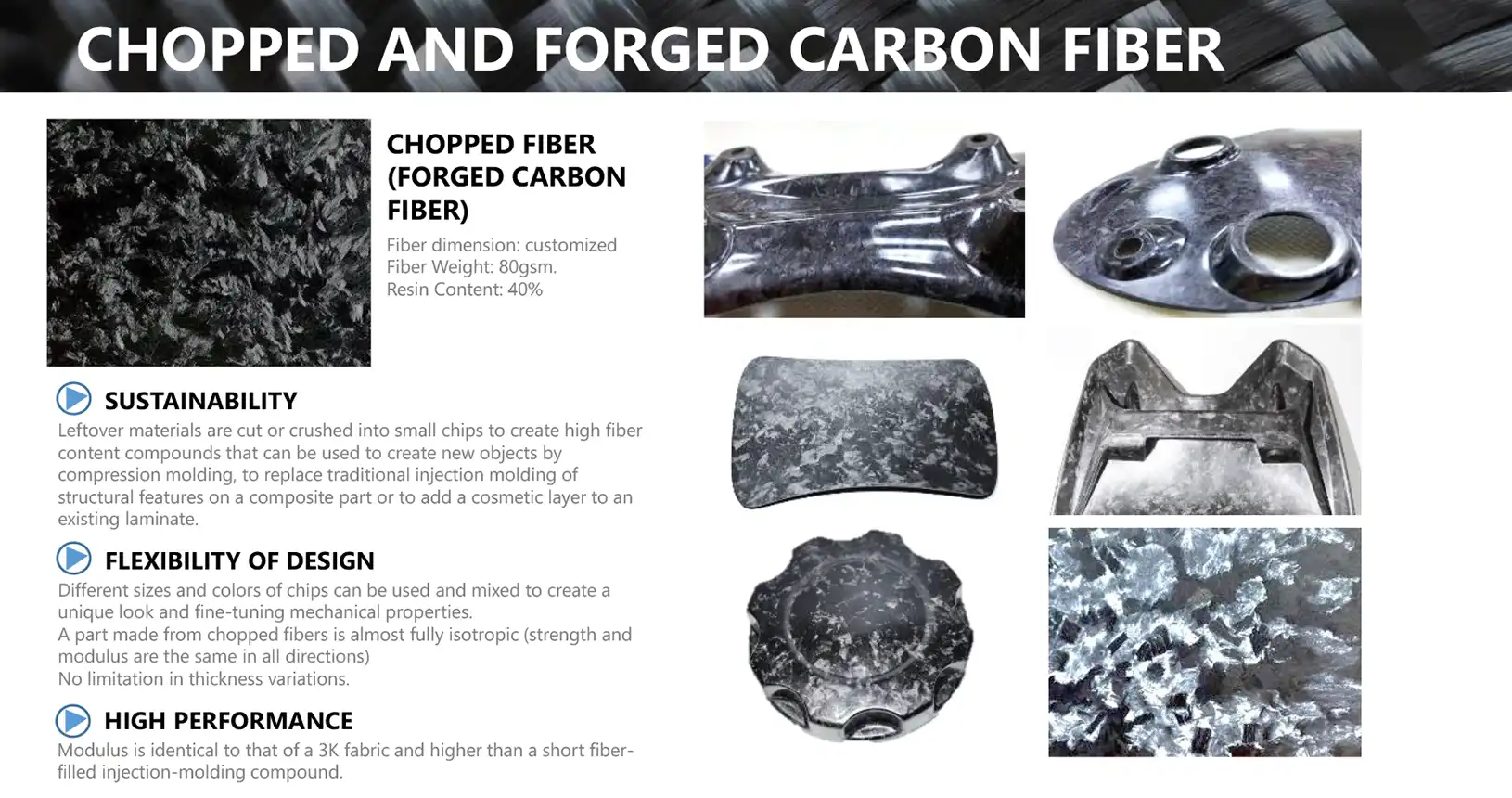

Carbon fiber. We are working with a new company that provides traditional carbon fiber applications for a wide range of products. They have also developed new process that allows them to use regrind that is put back in the process creating what many customers have been able to gain " green content " status for parts that use this application.

08

Liquid silicone rubber

LSR. We have two companies who are very experienced with both building tooling and also running production of the molded parts for LSR. LSR requires very high precision tools because of the nature of LSR and it's tendency to flash during the molding. Both of our vendors are very established and successful in this challenging area of manufacturing.